(928) 445-1180

722 E. Sheldon St.

Prescott, Arizona

- HOME

- ABOUT

-

SERVICES ▾

- AUTOMOTIVE

- |

- RESIDENTIAL

- |

- COMMERCIAL

- |

- SPECIALTY

- |

- SHOWERS

- |

- RVS

- |

- ADAS

- FAQS

- REVIEWS

- CONTACT

(928) 445-1180

722 E. Sheldon St.

Prescott, Arizona

110

We have over 110 years of combined experience working with glass, mirrors and windshield repairs and replacements. Our expert tradesmen get the job done right, every time.

Contact us today for all your car, home, business, specialty, shower, and RV glass needs!

A. Yes. Your right to choose any shop you please is guaranteed by Arizona law. Tell your insurance agent or glass

administrator you’d like to use Bennett Glass and Mirror in Prescott Arizona.

We’re approved by all major insurance companies to handle

all of your automotive glass claims.

Our tenured staff will handle the phone calls and paperwork. Our

techs will earn your trust putting their 15 years of experience to work on your assets.

A. No, according to Arizona law ARS 20-263: Insurance companies cannot raise your rates for any claims

that you did not cause or were not your fault which includes auto glass and windshield repairs or replacements.

Therefore, if your windshield got broken or your car vandalized and you were not at “fault” than your

insurance company cannot raise your rates.

A. Yes. We can replace all glass in your vehicle including back glass, side windows, side view mirrors, sunroofs, and custom glass for hot rods or marine applications.

A. It depends on your insurance company and the age of the vehicle. In some cases, the dealer glass may be the

only glass available for your vehicle.

Call us at (928) 445-1180 with your information and we can tell you if your insurance

company will pay for the dealer glass.

Our auto glass meets or exceeds original manufacturers' specifications.

A. We are able to perform modern chip repairs for most vehicles where the chip is less than the size of a

quarter and hasn’t been repaired previously.

While modern chip repairs do significantly reduce the

appearance of the chip, oftentimes the impact point of the break doesn't entirely vanish.

If the chip

is in your line of vision, we recommend replacing the windshield entirely.

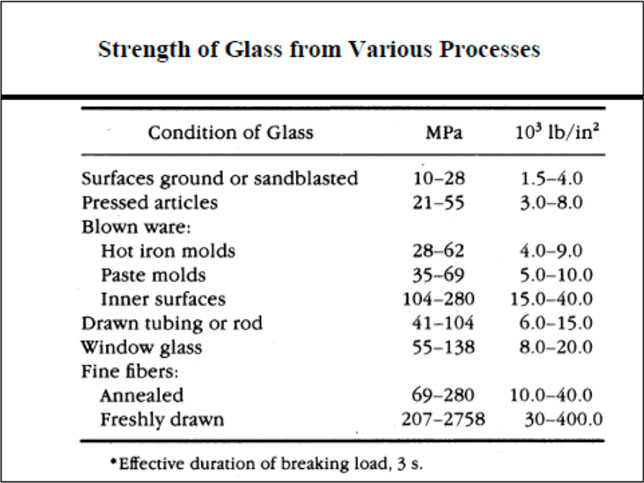

A. The thickness of glass needed for your project depends heavily on the intended use and loading.

Call or stop by to talk with our customer service representatives to get an exact answer.

Below are some general sizes and uses:

Glass shelving - 1/4” tempered is preferred.

- 1/4” annealed may be used for light loading in low traffic areas

Picture frames - most normal picture frames take single strength glass (3/32”).

- 1/8” is recommended for larger frames

Single pane glass - most single pane glass is double strength (1/8”)

Table tops - 1/4” is the minimum recommended thickness for table tops that are well supported.

- 3/8-1/2 “ thick is recommended for tops with less of a support structure.

You can browse our "Index of Glass Technical Documents" to find answers and more detailed information. We are also happy to answer questions at our shop, via email or phone.

Properties, Applications & Potential

Annealed glass is the basic float or flat glass that hasn’t been heat-strengthened or tempered and it tends to

break into large, jagged shards.

It is used in some end products and often in double-glazed windows.

With heat-strengthened glass, the cooling process is slower, which results in

lower compression strength.

Heat-strengthened glass is approximately twice as strong as annealed, or untreated, glass.

Before the glass can be used as a building material it is often heat-treated for durability and safety.

There are two different types of heat-treated glasses, heat-strengthened and tempered.

While the production

process is similar, heating the glass to approximately 1.200 degrees Fahrenheit and then force-cooling, the

cooling process in tempered glass is accelerated to create a higher surface and/or edge compression in the

glass.

This process makes the glass four to five times stronger and safer than annealed or untreated glass.

Fully-tempered safety glass is often used for other applications where safety is desirable, because of its

break pattern or when significant additional strength is needed to resist wind pressure, thermal stress or both.

Laminated glass or laminated safety glass is made of two or more layers of glass with one or more "interlayers"

of polymeric material bonded between the glass layers.

Poly Vinyl Butyral or PVB laminated glass is produced

using heat and pressure to sandwich a thin layer of PVB between layers of glass.

Laminated glass is used extensively in building and housing products and in the automotive and transport

industries vastly on account of its advanced safety features.

Laminated glass displays high-performance impact

and bullet resistance capabilities as well as fragment retention performance.

So, instead of shattering on

impact, it is held together by the interlayer which reduces the safety hazard from the shattered glass fragments.

But the interlayer also provides a way to apply several other technologies and benefits, such as coloring,

sound dampening, resistance to fire, ultraviolet filtering and other technologies that can be embedded in or

with the interlayer.

Insulated glass consists of two or more plies of glass separated by an aluminum or other types of spacer

and is filled with air or in some cases noble gases like argon to influence the element’s Ug value.

The

combination of two panels of glasses and the trapped air is what makes insulated glass a superior energy

efficient method of glazing.

Inherently, insulated glass demonstrates high thermal performance by reducing

heat gain in summers and heat loss and condensation in winters.

Among other benefits, the use of insulated

glass can contribute to lowering cooling and heating costs, UV transmission, while maintaining wind load strength.

Extra clear glass is created by reducing the amount of iron within its content which removes the green

tint inherent in standard glass.

Extra clear glass’s almost completely transparent appearance means it has

limited sun reflection properties.

It is particularly useful in solar energy applications where it is important

that the glass cover lets light through to reach the thermal tubes or photovoltaic cells.

Anti-reflective

properties can be further increased by applying a special coating on the low-iron glass.

It’s widely used

in windows or facades as it offers brilliant clarity, which allows occupants to appreciate true colours and

to enjoy true-to-life views.

Surface coatings can be applied to glass to modify its appearance and influence or improve its

properties, such as low maintenance, special reflection/transmission/absorption properties, scratch

resistance, corrosion resistance, etc.

Coatings are usually applied by controlled exposure of the glass

surface to vapours, which bind to the glass, forming a permanent coating.

The coating process can be

applied while the glass is still in the float line with the glass still warm, producing what is known

as "hard-coated" glass.

Alternatively, in the "off-line" or "vacuum" coating process, the vapour is applied

to the cold glass surface in a vacuum vessel.

Today, there are various decorative glass types offer a variety of design options for residential or

commercial solutions.

Acid etched is called the glass that has been chemically treated with an acidic

material, such as hydrofluoric acid, to produce a surface finish that will diffuse transmitted light,

reduce glare and has a “frosted” appearance.

The treatment on the glass is used to diffuse light, reduce

glare and obtain a translucent appearance. The treatment on a mirror is used to obtain a soft matted

reflection.

The treatment can be applied to provide different levels of translucence, either uniformly over

the entire surface or in selected areas creating decorative patterns.

www.glasscon.com/blog/8-common-glass-types-properties-applications-potential

www.libanswers.cmog.org/faq/144174#:~:text=The%20slight%20green%20color%20is,94).

www.glassproperties.com/references/MechPropHandouts.pdf